Medtech Company IME Medical Electrospinning Establishes New High-Tech Production Facility to Set The World Wide Standard for Ground Breaking Regenerative Medicine Solutions

Two new cleanrooms and a high-end laboratory enable the development and large scale production of electrospun scaffolds that meet the stringent requirements of the Medtech Regenerative Medicine Industry

Medical Technology company IME Medical Electrospinning, developer, producer and scientific partner in the field of biomedical electrospinning processes and equipment, today announced that its high-end laboratory and a brand new set of cleanrooms have become operational. With the commissioning of these essential high-tech assets, IME sets the standard in the co-development and production of scalable and reproducible nanometer and micrometer fiber scaffolds that enable the industry to develop medical implants that support the human body to auto-repair tissue of for instance heart valves, blood vessels, nerves, tendons, skin and bone.

IME's technological solutions are able to mimic the natural human extracellular matrix for implants in the human body in nanometer and micrometer format, applying various polymers. Human cells interact with these structures and MedTech products can be developed that lead to regeneration and the formation of new natural body tissue. This is in contrast to implants of traditional structures, which often are seen as foreign and therefore can lead to scar tissue or rejection phenomena.

Since the move to their new building in March this year, the company has been working unrelenting on realizing the laboratory with two new cleanrooms. From now on IME is able to not only develop and manufacture its top-end proprietary electrospinning machines, but to also produce the actual scaffolds for the intended medical implants for their customers. The cleanroom facilities will enable the production of Class I, II and III medical devices.

IME Medical Electrospinning develops scaffolds for a high variety of medical applications in close collaboration with an ever-growing portfolio of customers and partners worldwide within the industry, the scientific environment, hospitals and medical institutes. Multiple products manufactured using IME’s technology are now either on the market or in clinical development.

Ramon Solberg, Founder of IME Medical Electrospinning says: “We have brought the controllability, reproducibility and scalability of the electrospinning process to a level that enables the development of products that meet the stringent requirements of the MedTech industry. The new facility now enables us to also translate this knowledge into groundbreaking products together with our clients. It is amazing to work at the forefront of innovation for regenerative medicine applications.”

Judith Heikoop, Managing Director of IME Medical Electrospinning says: “We are extremely proud to have been able to expand our commitment with the regenerative medicine industry and foremost the millions of patients around the globe with the establishment of these state-of-the-art manufacturing lab facilities. This will further enable us to co-develop with the industry and regenerative scientists worldwide, the most innovative and ground breaking regenerative own body implants that have been unthinkable and unheard of up until now. A revolution that has only just started.”

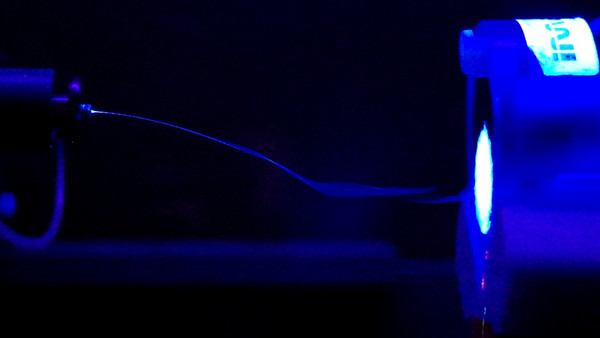

The video below shows how the special biopolymers are being pushed through the nozzle and being shot to the scaffold being built.