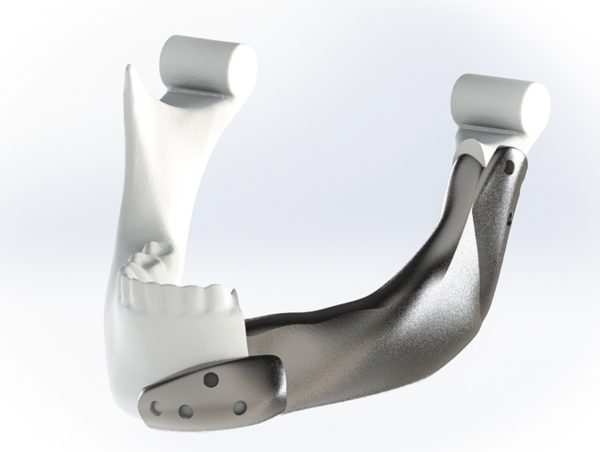

Revolutionary implant for reconstruction purposes after mandibular resection

Annually, worldwide 600,000 new cases are diagnosed with cancer in the head and neck. In a subset the treatment involves removing a segment of the mandible (lower jaw). To preserve aesthetics and essential functions, such as mastication, the mandible must be reconstructed. The standard for reconstruction is transferring bone including tissue from the patient's lower leg i.e. the fibula including muscle and skin tissue. This however is not feasible for some patients as a result of compromised vasculature of the lower leg. A medical graded Ti plate is then used to connect the remaining bone segments. M3DT is a Dutch company that has 3D metal printers that allows to produce patient specific implants. The public private partnership will be in the form of a joint venture with M3DT and the NKI-AvL as partners.

Societal impact: A subset of patients (~30%) is ineligible for such a procedure, because of vascular problems. These patients receive only a titanium plate and a local/regional flap to bridge the defect. These conventional plates tend to brake or loosen in time (~30% of cases). As a result, secondary surgery to replace the conventional plate is often required which places a major burden on the patient and reduces their quality of life. Producing an innovative, stronger, and reliable method to connect the mandibular segments can significantly improve patient care by eliminating complications. With respect to the economic impact, the cost per Quality adjusted life years (QALY) for the current treatment is €7963,-. Economic: The cost per QALY for the Rifram was calculated to be €7170,-. This is a reduction of about €793,- per QALY. Mean costs per patient per year was calculated to be around €500,- reduced with Rifram surgery compared to current treatment. The reduction in costs is largely due to the expectation of reduced complication rate.

Mobius 3D Technologies (M3DT), along with the clinical expertise from the NKI-AvL, extensively tested and developed a concept prototype implant that has the clinical potential to replace the conventional mandibular plates. Investigation: Based on plate failure data a novel mandible implant will be designed. We aim to provide evidence through model analyses, physical tests, and a clinical study (10 patients) that this new type of personalised mandibular implant is safe to use, results in significantly less complications and can be practically placed during surgery.

Deliverables WP1: Analysis of Plate Implant Complications and Failures, a retrospective study on the conventional plates demonstrated a high incidence of plate related complication, thus demonstrating the need for an improved, stronger and more reliable implant i.e. the Rifram implant.

Deliverables WP2: Detailed Design of Implant & Tools, a general improved clinically acceptable mandibular implant was successfully designed including the accompanying cutting guides.

Deliverables WP3: Stress Simulations. The stress simulations (FEM) provide evidence for the METC that the Rifram implant is mechanically stronger than the conventional plate.

Deliverables WP4: Experimental Testing of Implant. The fatigue mechanical stress simulations provide evidence for the METC that the Rifram implant is mechanically stronger than the conventional plate.

Deliverables WP5: Production Process & Quality Assurance. A standardised and certified method to produce a patient specific implant and corresponding tooling that ensures to deliver a safe and quality product is established.

Deliverables WP6: METC Application & Clinical Trial. The METC protocol has been approved, initiated, implemented in the NKI-AvL workflow and is currently ongoing, with two patients successfully included.

Deliverables WP7: Project Management. This WP relates to the projects technical and clinical documentation and dissemination. (Bi-) weekly meetings were held and the projects progression and tasks were discussed. Financial overviews and required PPP-allowance project documentation were submitted according to schedule. This WP will continue after ending of the clinical trial i.e. WP6.

Expected outcome: The patients included in the study should have good occlusion and will have no complications within the one-year follow-up period. Potential complications include wound healing problems, infection, foreign body reaction and fracture of the implant or the mandible. Implementation: If the new implant demonstrates to perform better, in terms of performance and reduction of complications, than the conventional plates, this would be a significant improvement. It would shorten surgery time, and a stronger reconstruction. The clinical study is still ongoing with 2 out of the planned 10 patients included. The clinical results are promising and after completion of the clinical trial is expected that the Joint Venture will become officially active.